While companies researched into Augmented Reality, they thought of conceptual applications of this technology in the mining environment. There was a great focus on applications that would optimize the mining process by reducing costs, improving efficiencies, increasing productivity, and enhancing safety. Another factor was how easily these technologies could be incorporated into current working environments such that there were minimal amount of human resistance and implementation costs.

Augmented Reality in Drilling

The accuracy and efficiency of drilling can be significantly increased through visual guidance assistance through AR. This visual technology can further be improved by displaying real-time location and orientation of the drill below the surface or the rock the machine is currently drilling.

Technologies such as low-frequency electro-magnetic location transmitting systems used in the oil and gas industry would allow for the exact location of the drill bit to be displayed. This would allow for a faster reaction and adjustment time by drill operators, allowing them to improve accuracy.

When AR is paired with other technologies such as directional drilling, which allows for control over the drill head during the drilling process, the drill can be steered in real-time to follow the exact path laid out in the plan. This improved accuracy leads to reduced wastage in resources and also reduces the potential damage of equipment as unknown hazardous objects can be avoided.

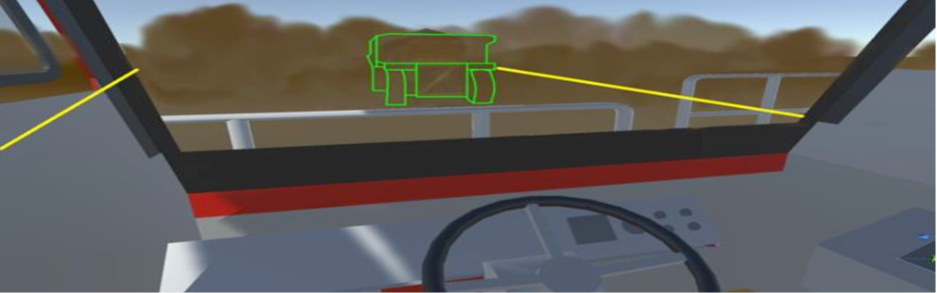

Navigation Aid and Operator Assistance

- Road Boundaries

- Approaching Vehicles

- Distance from Vehicles

- Distance to reverse to a particular site

- Video feeds of blind spots of a vehicle

Other useful virtual overlays could include information on remaining fuel capacity, current load, estimated duration until next refueling, vehicle speed, GPS guidance system, or real time location of key locations on a map.

Real-time information sharing between different operators and vehicles will improve feel efficiency, help with feel management, and improve communication and response times. All of these uses will help reduce costs, prevent accidents, and improve worker productivity.

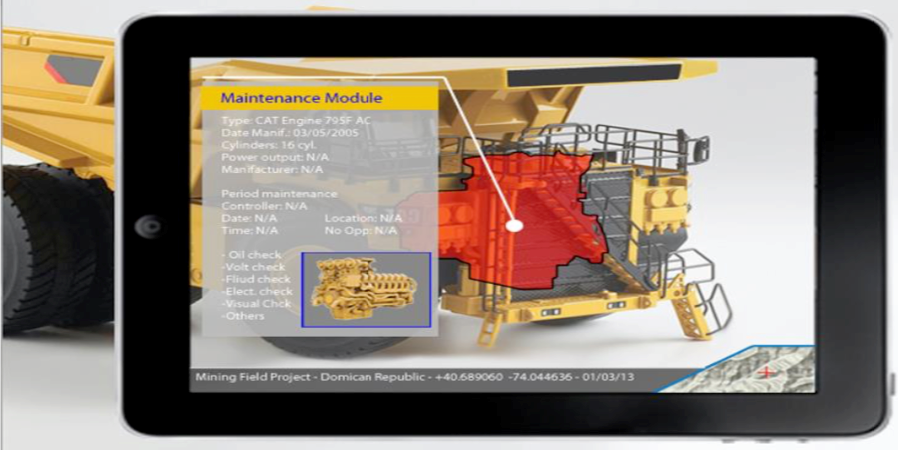

Maintenance and Repair

General repair and maintenance of machines can be done more efficiently through the use of AR. Essential information about the machine being repaired could be displayed when the appropriate part breaks down. This can also include a step by step interactive process that allows operators to see how to fix the particular part. Key points of data to assist with the repair such as how much pressure to apply when adding a part, or how much torque to use when fastening a piece of equipment, can also be shown to minimize errors.

AR will help reduce repair time greatly and will also ensure the repairs and maintenance are done properly, so that the machine can operate longer before having to come back for servicing.

Augmented Reality in Industrial Manufacturing

Similar to mining, AR can help improve efficiencies in the manufacturing industry as well. The more common device that will be used here is AR headsets, which are expected to reach sales of approximately 20 million by 2021. Some of the core areas to improve, such as safety, improved logistics, and maintenance are quite similar to the mining industry, however, the way the technology is applied differs in both industries.

Hands-On Training

This also reduces the barriers to entry to the industry, as lesser technical experience is required to operate the machines. This will help improve labor quality and satisfaction as workers will now have on-demand access to assistance without fear of breaking or damaging machinery or harming themselves.

Streamlined Logistics

AR can allow these workers to pull information from a database and view what they need instantly without having to move to another location or communicate with another employee. They can check on order statutes, invoice numbers, time of departure of the next shipping truck, and other key points of data from where they are working. This can allow them to work significantly more efficiently as they no longer need to find the right person to get information they need and can do so independently and instantly.

Product Design and Communication

Typical product design procedures require large amounts of drawing and communication between different parties. This can often be a lengthy and resource-intensive process.

AR can reduce the time spent during this process by allowing multiple people to view a real time projection of drawings and designs in front of them. This way, meetings can be held virtually, and communication can be done significant faster versus emailing designs and consolidating feedback from multiple replies.

Conclusion

There are multiple advantages of augmented reality in both the mining and industrial manufacturing industries. Since both of these industries involve the use of highly complex machinery to preform specific tasks some of the common areas of improvements include higher efficiency when using machinery through AR navigation and guidance, improved maintenance through virtual instructions, and better communication and modelling through virtual conferences and sharing of information.

Sources

https://www.researchgate.net/publication/314838396_Potential_Augmented_Reality_Applications_in_the_Mining_Industry

https://blog.thomasnet.com/augmented-reality-manufacturing?utm_content=76098134&utm_medium=social&utm_source=linkedin